You probably know that Apple, Nvidia, Qualcomm, Samsung and just about anybody else who makes processors is stuffing their products with circuitry to accelerate AI tasks. What you might not know is that AI is also being used to accelerate the design of those very processors.

Case in point: Intel. The Santa Clara, California-based company plans to detail its new Meteor Lake processors on Thursday, products it hopes will transform laptops into what it calls «AI PCs.» But Intel also used AI to create those processors.

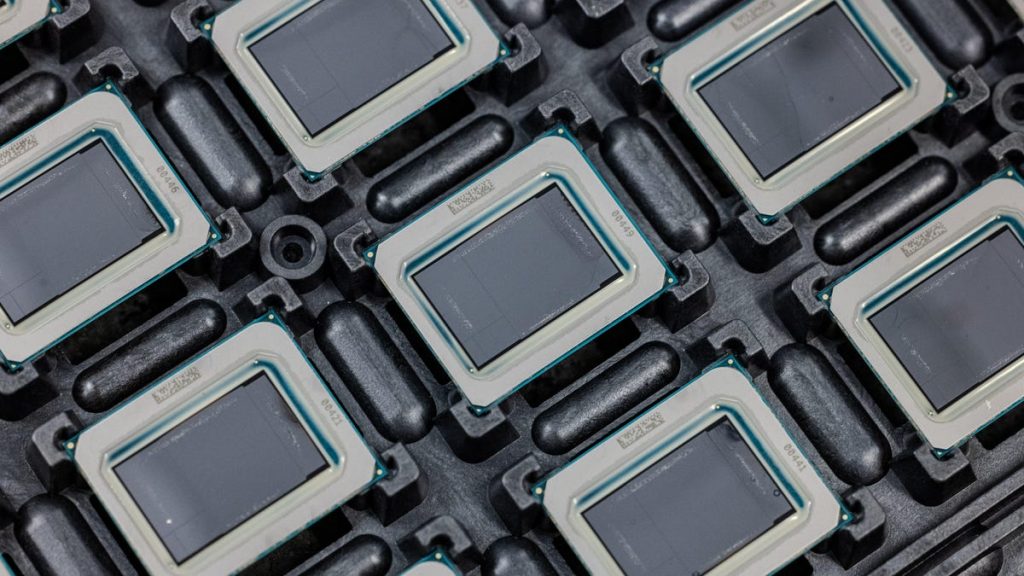

AI tools catch bugs early in the design process so chips come to market faster, and they oversee manufacturing so more of the tiny slices of silicon that Intel makes end up inside products instead of in the trash can. For Meteor Lake, Intel’s first major processor made of multiple «chiplets» stacked into one package, the AI tools help find the best way to sell each processor given a multitude of slight differences in each processor’s components.

With these AI tools, «the amount of sellable units is increasing significantly,» Shlomit Weiss, a co-leader of Intel’s Design Engineering Group, said in an exclusive interview.

See also: Inside Intel’s Chip Factory, I Saw the Future. It’s Plain Old Glass

That’s key for Intel, a company scrambling to reclaim chipmaking leadership lost to Taiwan Semiconductor Manufacturing Co. (TSMC) and rebuild the US industrial base. And if you’re one of the millions of people who uses a Windows PC, it’s important for you too, since better manufacturing means laptops that perform better and cost less.

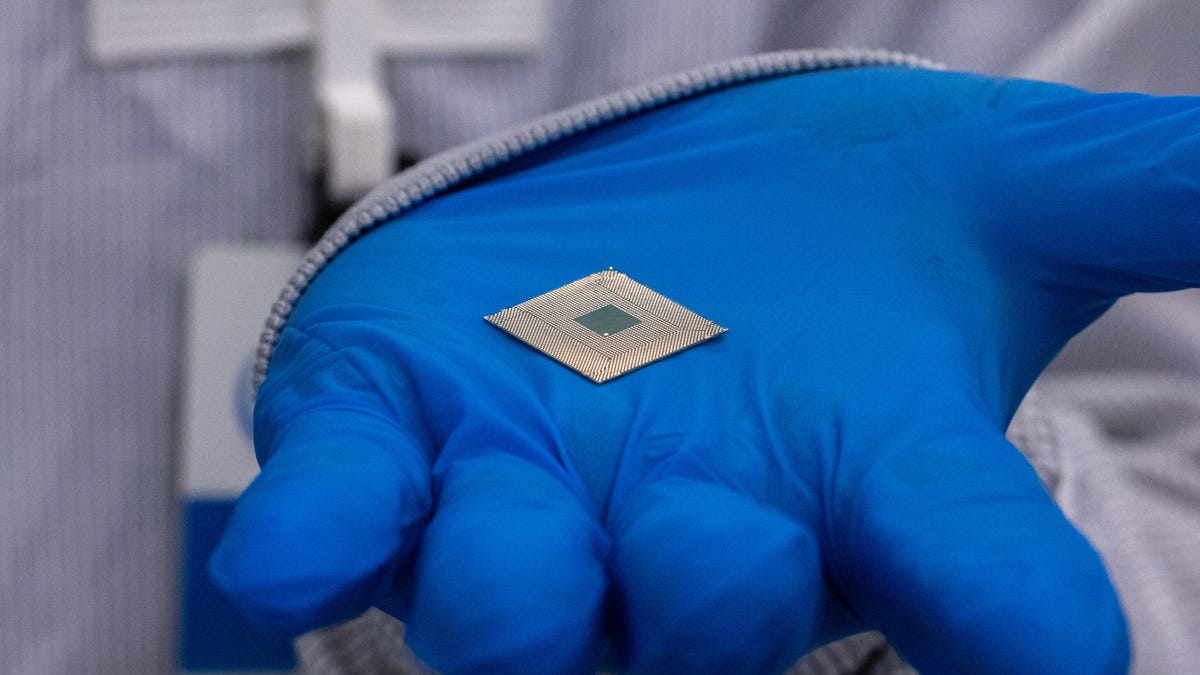

Processors these days consist of tens of billions of tiny electronic on-off switches called transistors. Information in the form of ones and zeros cascades through them to spell-check your resume, calculate your income tax and sharpen that picture on your phone. Figuring out how to optimally arrange all those transistors and to check that they’ll perform as needed is beyond any human, so computers have long been essential to the processor manufacturing business.

But using AI is a new wrinkle. Artificial intelligence systems, trained to recognize patterns in complex real-world data, can perform tasks like screening out spam and identifying your face in your phone’s camera roll. Now they’re helping humans to get a better handle on processor production.

«As Moore’s Law progresses and we get more and more transistors, you can’t hand-tune everything anymore,» said Real World Insights analyst David Kanter.

Intel isn’t alone. Cadence and Synopsys, two major makers of the software tools used to design processors, offer AI-boosted tools to lay out processor elements. Google has described how it used AI to develop its AI acceleration processors. And Nvidia, the top AI and graphics chip designer, has used AI extensively to replace much slower traditional computing processes in creating its products.

One type of AI used in the technology is called reinforcement learning. In it, an AI system explores a range of options and is rewarded when it finds outcomes that come closer to a desired goal. «That reinforcement learning can potentially take the human out of that loop,» said Elyse Rosenbaum, a professor of engineering at the University of Illinois.

Intel is combining AI tools from outside chip design companies with its own internally developed tools, said Weiss and her co-leader, Navid Shahriari. Some examples of the internal tools:

- While simulating new designs, Intel AI analyzes bug reports and categorizes the bugs, work that lets human engineers get to work sooner on fixing the problems. «It can save a few hours for several people per day,» Weiss said.

- Intel has begun testing generative AI tools that process the detailed written specifications for a chip to create tests that actually ensure chip designs meet those specs. People do that work today, but they can make mistakes, Weiss said. Intel is using OpenAI’s GPT, a large language model that’s been modified for Intel’s particular needs, running internally on Intel’s own systems.

- Intel uses AI to scrutinize chips coming off the manufacturing line, each of which has slightly different characteristics like clock speed, cache memory size and power consumption. The AI system can look at this complex collection of interrelated details and find the best way to fit processors into one of the various versions Intel will sell, Shahriari said.

Finding the best way to sell a chip is more complicated with Meteor Lake since it’s got multiple interlinked chiplets, also called die, which means many more combinations of all those characteristics to analyze.

But the AI system can find the right balance, meaning a higher yield — the fraction of chips that are usable.

«You can find that sweet spot of the multiple die that’s on that one Meteor Lake device,» Shahriari said. «It not only maximizes the yield but also gives you performance and power improvement.»